|

|

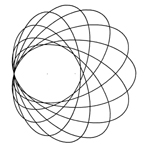

Ovalturning is an old turning art, which has been practiced in Europe since the 16th century, in order to produce oval articles. There are examples in museums such as those in the ivory collection of the Green Vault in Dresden [1.1.5] ¹). Figure 0302 shows an oval turned lidded goblet by Egidius Lobenigk, dated 1586. Lobenigk was one of the famous court turners of Elector August of Saxony, who governed 1553 - 1586.

1586 Dresden State Art Collection Dresden Grünes Gewölbe (Green Vault) [1.1.5]

The

turners and mechanics working at the European courts were the creators of the

lathe mechanisms which allowed ovalturning and other complicated turned artworks

to be produced. It was, above all, the oval chuck, the invention of which is

attributed in principle to Leonardo da Vinci (1452 - 1519), which allowed the

production of accurate elliptical forms. The court turners were also required to

instruct their sovereigns at the lathe and to educate the princes in the correct

form of manual work [1.1.3].

Oval picture frames, for which the elliptical form was particularly appropriate, became very fashionable in the 19th Century when portrait photography spread. Oval frames for pictures and mirrors were turned, by hand, at ovalturning lathes in great quantities in frame making factories. Such frame factories were to be found throughout Germany but today, unfortunately, none remain. In the "Handbuch der Ovaldreherei" (Handbook of Ovalturning) of 1920 the production of oval frames is described in detail [1.1.1]. In the USA one frame factory, founded in 1864 by German immigrants, remains preserved as working museum [2.1.7][2.2.1][2.2.10][6.2]. One can study there the function of the ovalturning lathes of the 19th century. Since ovalturning required special skill the ovalturner was, among the turners, a well paid specialist. The ovalturning of frames disappeared from the workshops and factories when oval frames went out of fashion and particularly when faster milling machines were introduced. However, the variety of profiles obtained by ovalturning could not be achieved by milling.

Although ovalturning has lost its importance as production technology today, it is of increasing interest to artisans, the restorer and for those turners who want to experience the stimulating characteristics of ovalturning. There are substantial differences between the use of hand tools when ovalturning compared to the tool use when plain (or circular) turning..

There is only one specialist requirement for ovalturning, and that is the Oval Chuck. These chucks were commercially available until the 1950´s. Today these early chucks are only found by chance. Some individual turners have built themselves oval chucks based on old models. There is even an instruction to build an oval chuck from wood for study purposes [1.2.4]. Johannes Volmer, from Chemnitz/Saxony, has been involved with ovalturning and designing ovalturning devices and lathes since 1980. One of his prototypes was used by the Australian lathe manufacturer VICMARC [5.1]. Dan Bollinger in the USA [6.3] has built a variant of the Volmer lathes, and other turning suppliers are following. In March 2006 the craft supply SteinertÒ / Germany presented the small ovalturning lathe picOval [5.4].

While the capacity of the classic oval chuck is limited by its imbalance and while its moving parts have to be constantly lubricated and maintained, these disadvantages are eliminated with the Volmer Ovalturning Lathes ODM (Ovaldrehmaschine) - which run smoothly at high speeds usual for turning wood.